TB20-1 is based on the experiences from previous models within the 6T range of similar kind of melting and tempering machines – and then supported by new technology. The outside stainless steel surface makes it very easy for the operator to keep the entire tempering machine in a clean and nice condition.

The tempering machine is controlled by a PLC, and this technology offer you the following features:

- The entire machine is controlled from the touch panel, which has a graphics that intuitively guides the operator through the options available.

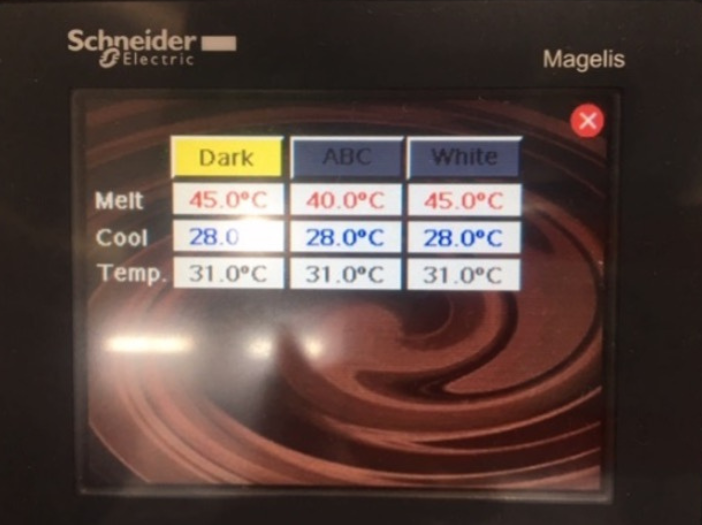

- The temperatures in the tempering process are set by the operator, and each temperature is independent from other temperatures. The operator can bring temperatures close to the limits of the standard recommendation – and further if required.

- In total 3 combinations of tempering temperatures can be stored. This ensures the same tempering result tank after tank – day after day.

- The machine can be programmed to start tempering at a pre-defined time. It means that well tempered chocolate can be available at any time: In the morning when the staff turns in – after lunch hour – or at any other pre defined time.

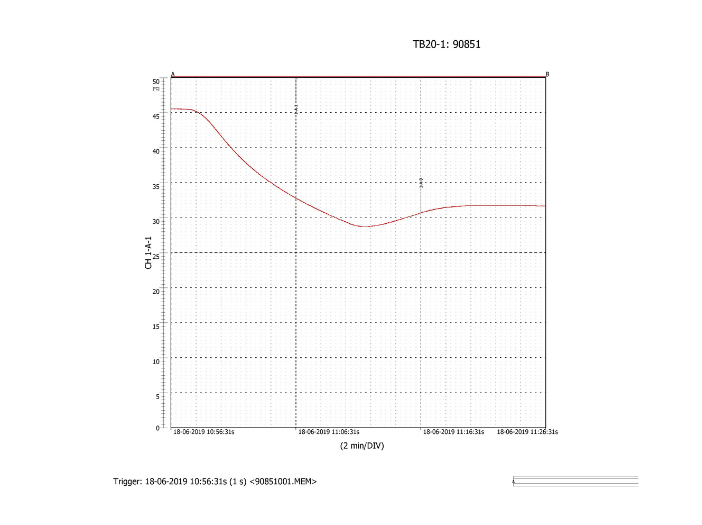

- The temperature progress during the tempering process can be visualized for later inspection.

- The machine has a smooth stainless steel surface for easy cleaning, and the agitator can be lifted up from the tank without using of any kind of tools.